As a manager, I was trained in something called “resource utilization.” I was frequently asked by the layers of leaders above me to provide them with justification for why the people who worked for me existed. I was asked to report on the number of projects they handled at a time, who was busy and who wasn’t, and who was able to handle more work than others. My job as their manager was primarily as the assigner of work.

Since I was controlling which work was assigned to people in my group, I needed a map that showed me what everyone was already assigned so I could find the people with less to do and give them any new work that landed in my inbox.

“You only have two projects? You can handle three. Here’s a third.”

Because of my style of top-down control management, I needed the groups under me to be arranged into functional silos. Functional silos primarily serve to organize employees into manageable departments to which it is easy to assign work and ensure that costs are controlled by only keeping the number of people that can be kept busy. All of this in the name of efficiency.

Later in my career, I learned that this pursuit of efficiency was highly inefficient and ineffective. It turns out that utilizing everyone to the maximum of their capacity is one of two big reasons that work takes so long to complete.

Introducing Little’s Law

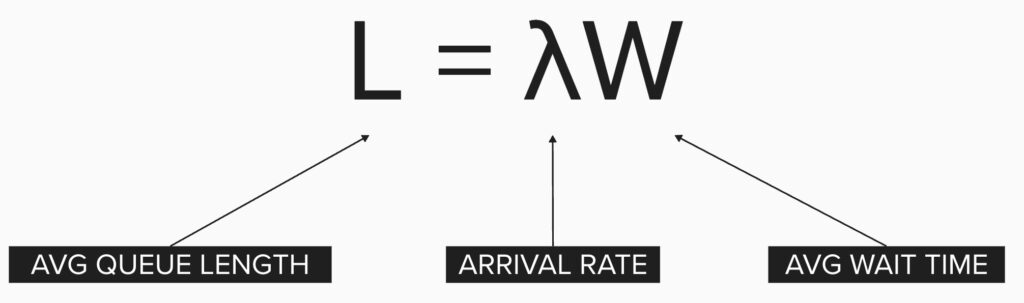

In 1961, John Little, a professor at MIT who studied physics and later marketing science, put together some researching into what we know today as queueing theory. Little’s Law states that

The average number of customers in a stable system (over some interval) is equal to their average arrival rate, multiplied by their average time in the system.

He expressed his math like this:

For it to work, the system being measured must be stable: departures and arrivals must equal each other. In other words, nothing can enter the system unless simultaneously something else exits. When something exits, something must enter.

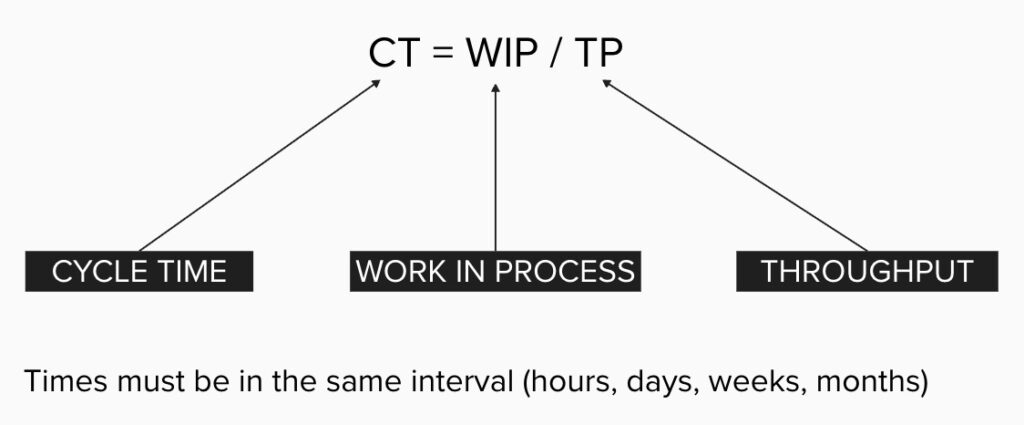

The math for this is only a little interesting to us, because this equation measures arrivals. If we base the equation on departures from the system, then we can use a different one that uses more familiar measures:

Cycle Time is how long it takes for something to go from started to finished. Most human activity that is done for some outcome rather than enjoying the journey is preferred to have a lower Cycle Time. If this equation is true, then we can reduce cycle time in a stable system by increasing throughput or by reducing WIP.

Increasing throughput (the number of items completed in a time period) is possible by leaning out a process and removing wasteful activities. But the gains are meager until you attack the easily controlled variable WIP. WIP is Work-In-Process. It is often also called Work-In-Progress. Either will do.

The equation proves out what can be tested time and again: by removing the number of items in any stable system, the system will flow faster. This means that the more we utilize the system, the more slowly the system performs. We don’t see this behavior in machines. A large factory machine like a kiln or a paint dry room does not operate more slowly if you fully utilize all available slots.

But the entire factory line? That’s a problem. And what about a functional work group? What happens when you take a team of software developers, project managers, marketing specialists, artists, designers, or just about any other sort of knowledge worker and you “load ’em up?” They slow down.

The performance of the system can be imagined on a normally skewed curve. At one end, a completely unutilized system collapses because there is nothing for it to produce. Some WIP is necessary for it to produce anything. As utilization increases, production increases. However, there is a tipping point on this marginal curve where increasing utilization starts causing a net loss of production until at absolutely perfect utilization, the system flows incredibly slowly.

Cycle Time goes way up as WIP increases.

Time for a Roller Coaster Ride

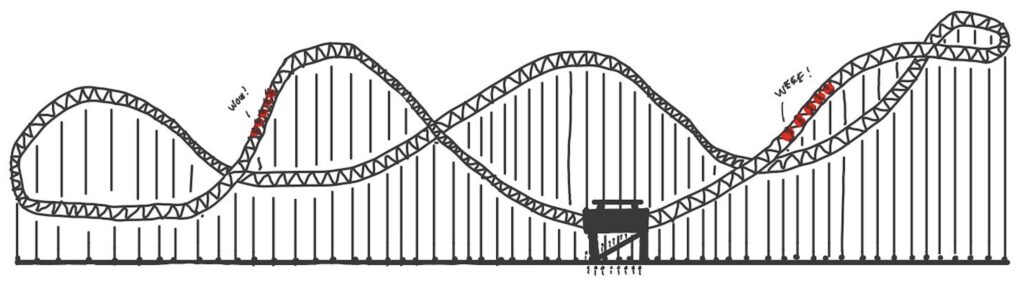

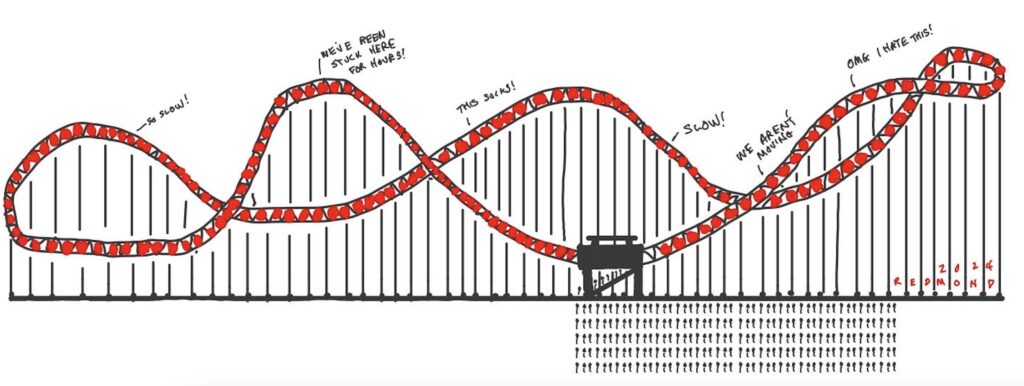

To make this more accessible, imagine a roller coaster. I drew one here for you so that you don’t have to imagine it. There are two cars on the roller coaster zooming along. The riders are screaming with a mix of terror and joy. The cars are traveling at around 20 mph, but the people on board feel like it is going 100 mph. It’s a thrilling ride for everyone.

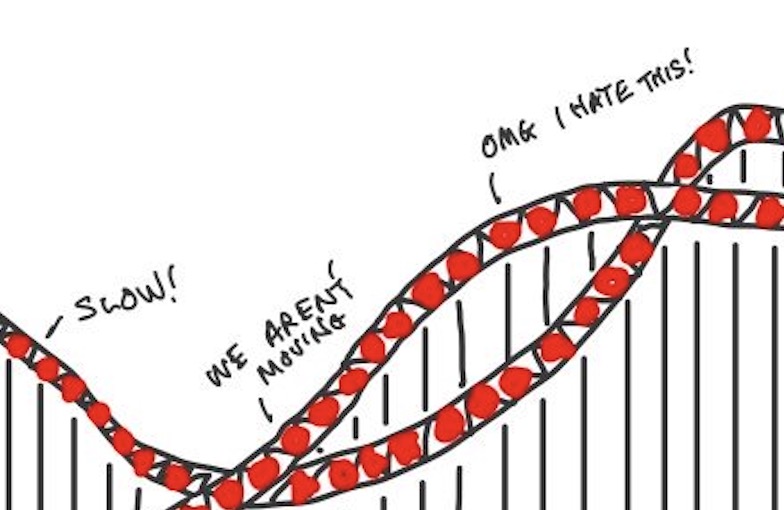

But a manager comes along and says, “What is all of that empty track doing while no cars are on it? I’m not getting my money’s worth! Make sure every inch of that track is fully utilized!”

So, we load up the roller coaster track to get the manager off of our backs. Now every inch of roller coaster is covered in roller coaster cars. How fast are the cars moving now? Is anyone having fun? Is the roller coaster productive? Sales will drop, not just because of the ride being slow and no fun, but also because of the huge queue that will form in front of the ride. While standing in that line, those people are not spending money elsewhere. We are suffering a cost from them being idle. Also, the people entering the coaster and exiting the coast are slowed. There are fewer rides generated. And everyone is trapped on the coast for hours while traveling tracks that used to provide a one minute long thrill ride.

The same thing happens to work in a department. If you start too much work, then too much will be going on at once. Your department will grind to a halt. If you believe that cost control and efficiency is as simple as doing as much as possible with the fewest people, you will end up saying things like, “It feels like we never really finish anything.” I can share with you what I saw happen:

- Deadlines were almost always missed and pushed until later

- Every project had a status of “watermelon” – green on the outside, red on the inside

- Everyone’s calendars are booked up solid causing work to be done in overtime hours

- Because everyone is so busy, any meeting to discuss things would be scheduled far into the future. Sometimes weeks out.

- The slow pace of things happening meant that no one really felt a sense of urgency. How can anything be urgent when no one is available?

- Everyone that placed work into the system desired for theirs to be treated with special handling and bypass all other work in an expedite process.

- No one can learn anything new from one another or has time to get or give help. Everyone is fully loaded all the time.

- If we had to move an effort from one person to another, there was nowhere to put it.

- We were always someone getting the flu or quitting away from system collapse and having to inform stakeholders we could not deliver.

- People’s home life suffered as we adopted a culture of hard-charging logging back in when we got home.

Worse yet, attempts to fix this situation usually made things worse. Inevitably someone would come up with a very important and urgent thing to work on, and we would say something like, “We need to get started on this right away! We need to get ahead of things so we get this done sooner!” And doing exactly that would make us finish it even later.

God help anyone who attempts to use an expedite or special handling process to speed things up. Such a practice only creates an effect called Flow Debt. When an ambulance plows through traffic, everyone else has to slow down and pull over to let it pass. While the ambulance gets through more quickly, everything else goes even more slowly.

The Fix is Limiting WIP

The fix is in the equation: Stop starting and start finishing.

- Invest in developing a culture of pulling work rather than pushing work and assigning it to people

- Everyone must be able to say, “No.” Always saying “Yes” leads to increasing WIP.

- Learn to determine which work is most valuable, preferably without dumping this decision-making on unempowered workers who will then suffer the wrath of powerful people, and only work on the more valuable things.

- Consider that 80% of the value that your department could produce is probably within only 20% of the requested work. Only the most valuable things should enter the system.

- Place limits on WIP and when things start to slow down, restrict the limits even further instead of trying to relax them. Relaxing WIP limits will cause work to slow down even further.

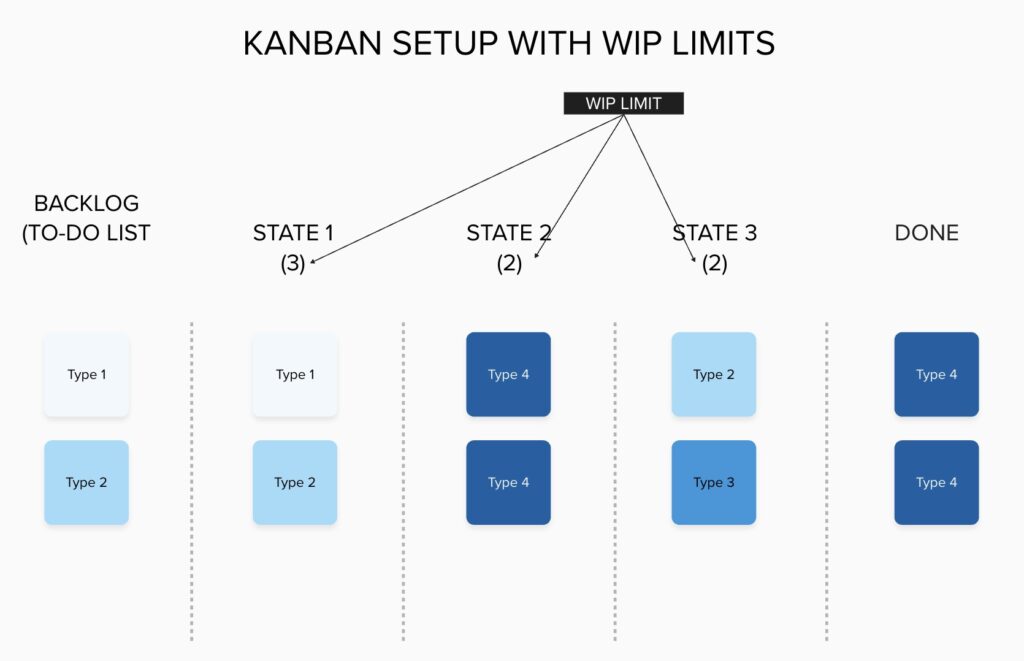

- Build a visualization system, such as in Kanban, to be able to see how much WIP there is and force WIP limits to be observed.

- Stop complaining about people not having enough to do. That isn’t important. You cannot save money by laying off people until everyone is fully utilized. Having people fully utilized will just increase the cost of the queues and the slowed cycle times you will create.

- Focus on availability. Everyone should have a large amount of available time when doing knowledge work. Availability gives space for innovation and collaboration. It speeds delivery. Available people learn new skills. Available people come up with new ideas and are more creative. If you are thinking that you can accept if people should be 20% available, I have bad news for you. The number is closer to 50% for knowledge workers.

Many organizations have adopted Scaled Agile (SAFE) as an operating model for their delivery teams. However, they frequently leave out one of the most important components that makes SAFE provide any benefits to them: the WIP limits on work. During PI Planning, the Agile Release Train’s Product Manager is asked to bring The Top Ten Features. That’s because the limit is ten. Eleven features is too many to get done in five sprints of work if the train and the teams are properly configured. One of the great lessons SAFE has to teach businesses is to organize around value. That means more than forming teams around products. It also means to structure decision making around value.

Not everything we are working on is of equal value. A lot of it is potentially not valuable.

The Limit on WIP Limits

There are powerful forces that prevent organizations from limiting WIP. The solution to this is a culture that empowers employees. If decision-making is moved from high levels of management to self-managing teams which are aligned to particular requestors, those teams have the ability to limit the work that they are doing in rational conversations using a fixed capacity model where the most valuable things are chosen first.

WIP Limits are a keystone feature of any organization that speeds their delivery and improve quality. Pushing work to people, forcing things to be started, assuming everything is valuable, and always adding more capacity to handle every request is how companies end up wondering why they are so slow. This is how you do twice the work in half the time: You do far less of the work you were doing before, because most of it was the less valuable work.

Empowered teams allow people to limit WIP. Limiting WIP creates a pull system. Pull systems create transparency. Transparency is necessary for continuous improvement. Leaving out the limitations on WIP from any business process overhaul is a gigantic miss.

Reinertsen, Donald G. The Principles of Product Development Flow: Second Generation Lean Product Development. Celeritas Publishing, 2009

“Little’s law.” Wikipedia, The Free Encyclopedia, 22 Nov. 2023, https://en.wikipedia.org/wiki/Little%27s_law

“Visualize and Limit WIP, Reduce Batch Sizes, and Manage Queue Lengths.” Scaled Agile Framework, https://v5.scaledagileframework.com/visualize-and-limit-wip-reduce-batch-sizes-and-manage-queue-lengths/

Goldratt, Eliyahu M., and Jeff Cox. The Goal: A Process of Ongoing Improvement. North River Press, 2004

Vacanti, Daniel S. When Will It Be Done?: Lean-Agile Forecasting to Answer Your Customers’ Most Important Question. Daniel S. Vacanti, Incorporated, 2020. ISBN: 978-0986436376

Vacanti, Daniel S. Actionable Agile Metrics for Predictability: An Introduction. Daniel S. Vacanti, Incorporated, 2015. ISBN: 978-0986436338